Showroom

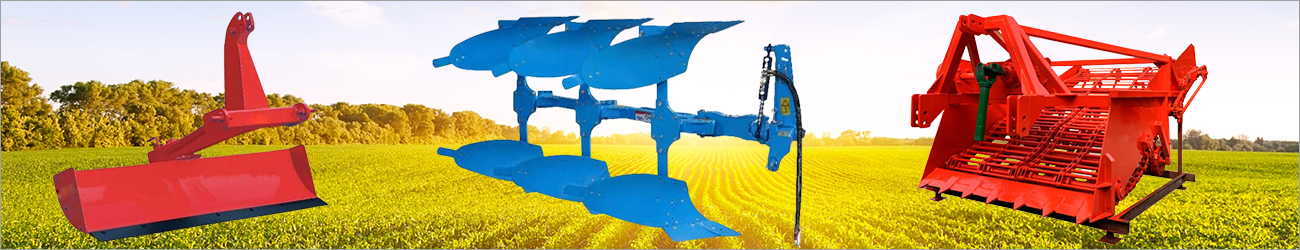

Agricultural machineries are used in farming and other forms of agriculture. Different varieties are available in these machineries like hand tools, power tools, tractors, and more. Agricultural machineries reduce the time & energy and provide the farmers with ease.

Rubber plantation machines and accessories

are constructed of rubber and can be used to press down on a surface so that

ink, paint, or other materials can be transferred onto paper, fabric, or other

surfaces. These are used in various applications in many different sectors.